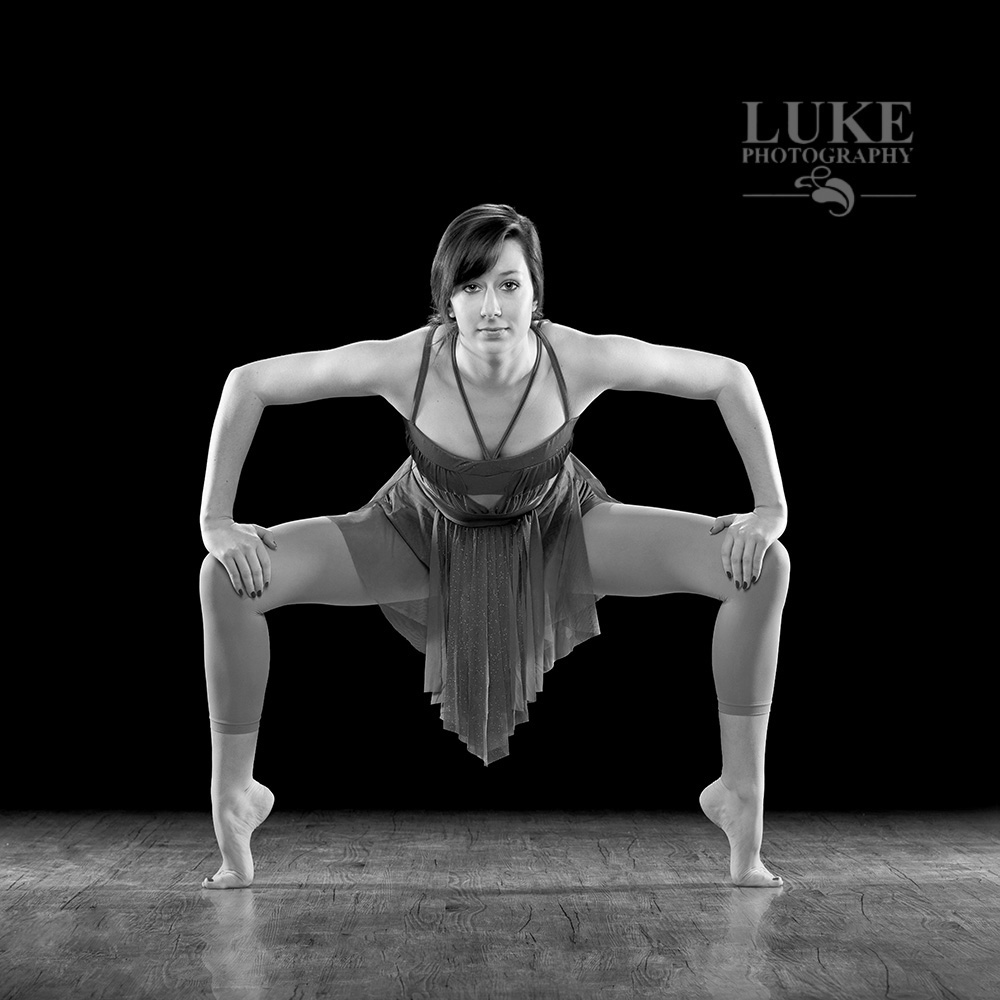

I had an intern at my Fairport studio for the months of December and January, and I wanted to take advantage of the fact that she was a dancer by having a dance-themed session before she returned to college for her spring semester.

Emily brought in a variety of dance outfits that she had worn to dance competitions while she was still in high school and we picked out several that we wanted to work with. The lighting for the majority of the setups was consistent: two striplights on either side of her acting as main lights, and a large octabox in front of her...over the camera....acting as fill light to soften some of the shadows that would appear on her face from the strong sidelight.

For the final setup,we moved into the daylight-lit studio for a ballet setup using softer window light. I set up apiece of burgundy fabric to camera left to act as a stage curtain, and had Emily posed on the floor putting on her pointe shoes. The background was the bare brick wall of the studio.

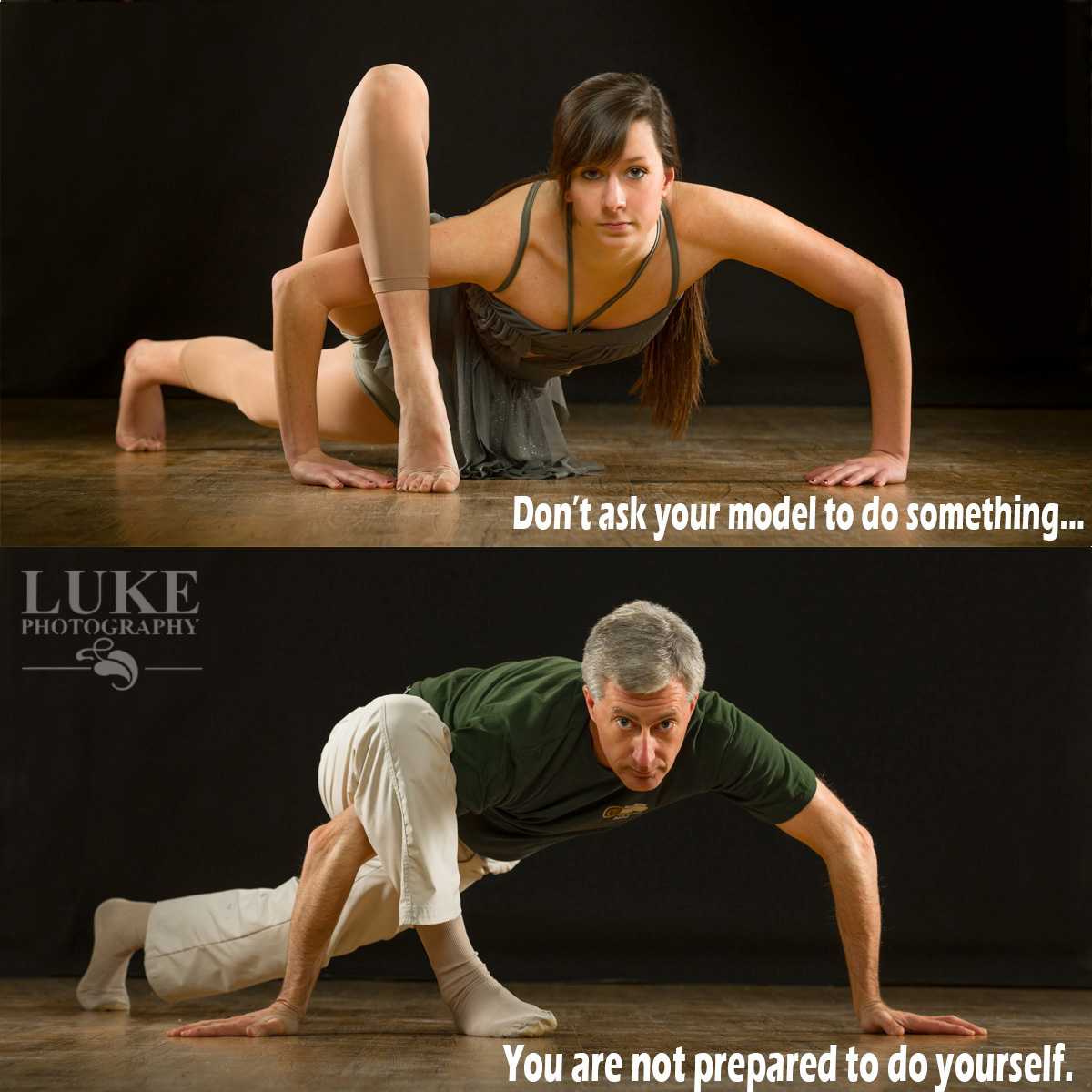

As I watched Emily suggest a number of poses that she has seen in magazines and dance publications, I had her make subtle position changes so that the resulting photo would look as good as possible. She had to hold some of these ridiculously technical positions for extended periods of time until I was satisfied with the results. She was being a real trooper, but I felt like a hypocrite sitting comfortably on the floor while she was posed in very physically-challenging positions, so I offered to switch with her and have her take my photo, so I could feel what it was like to hold those positions. Granted, I am more than 25 years her senior, but she was seriously impressed that I was even able to get in position, hold it, and get out of it without the need of a crane, hospital traction, and a wheelbarrow full of Advil.